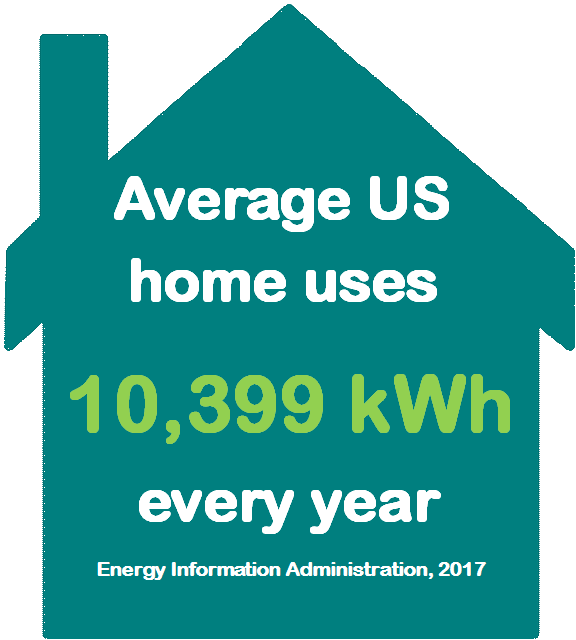

To date, Vehicle Reman customers have saved or avoided 10,515 mWh of energy – enough to power over 1,000 homes for a year. Using data from the Carnegie Mellon University Green Design Institute (2015) Economic Input-Output Life Cycle Assessment (EIOLCA) model (http://www.eiolca.net/), remanufacturing and reconditioning vehicles has realized this and a lot more savings. We’ll update the blog for water and pollutant savings in the future. Many companies pay money for sustainability. With reman, you get sustainability and cost savings; that is, this sustainability initiative does not cost money, it saves you money. We save customers ~50% off their vehicle CAPEX spend – it is the best combination of fleet finance and the environment. Legacy fleet best practice calls for retiring vehicles well before the value is consumed. Spark plugs now last 100,000 miles – it might be time to update fleet management. When maintenance and repairs mount, use reconditioning to extend your vehicle lifetime. When power trains fail, use remanufacturing to reset the vehicle to a zero-mile condition, get a 3-year, 100,000-mile power train warranty and create a new depreciation event (or expense the cost based on your preference). This approach, a fleet management best-practice, gives you three vehicle ‘lifetimes’: the new vehicle, the reconditioned vehicle and the remanufactured vehicle. What could be better for operating budgets and the environment?